Range of Spouted Pouch Filling Machines

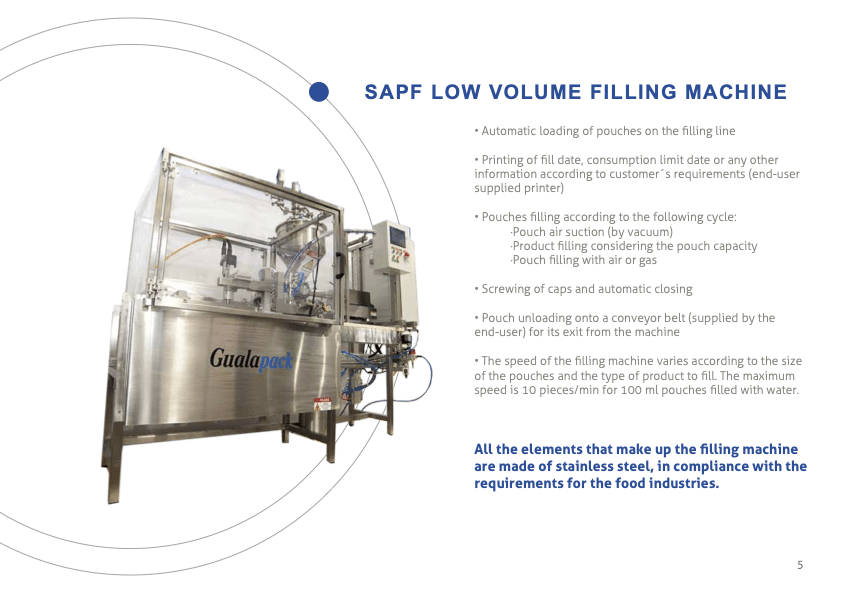

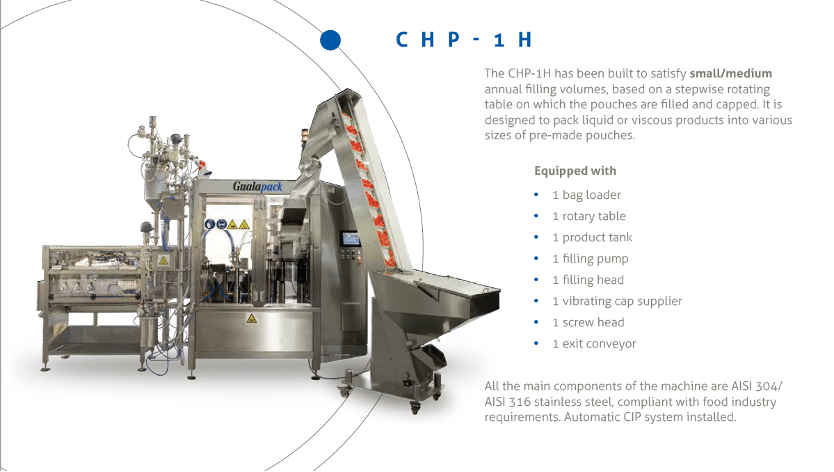

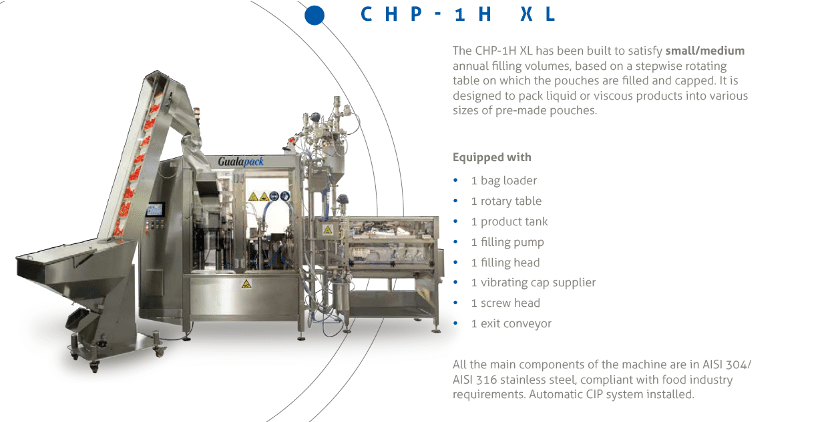

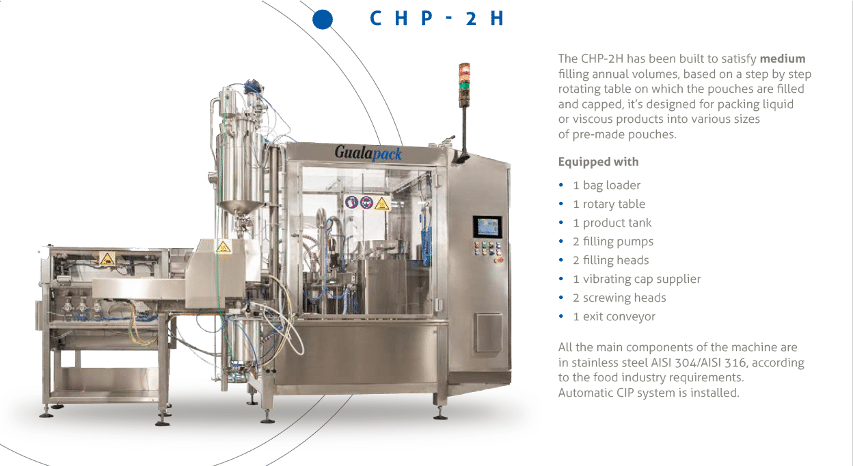

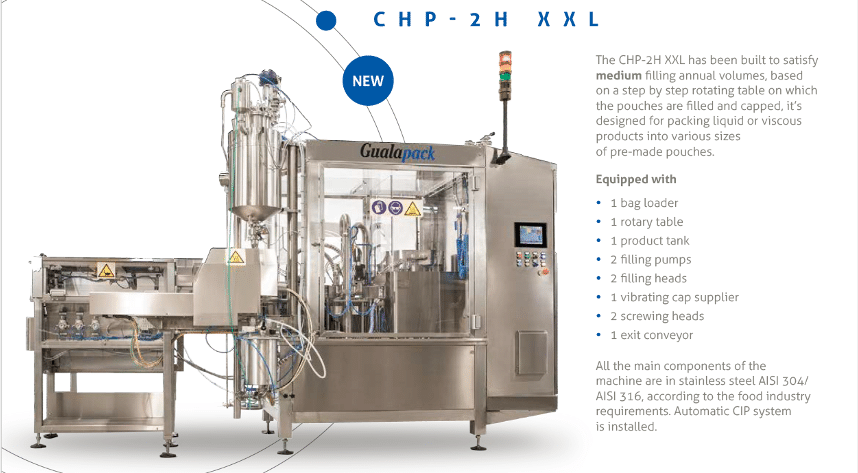

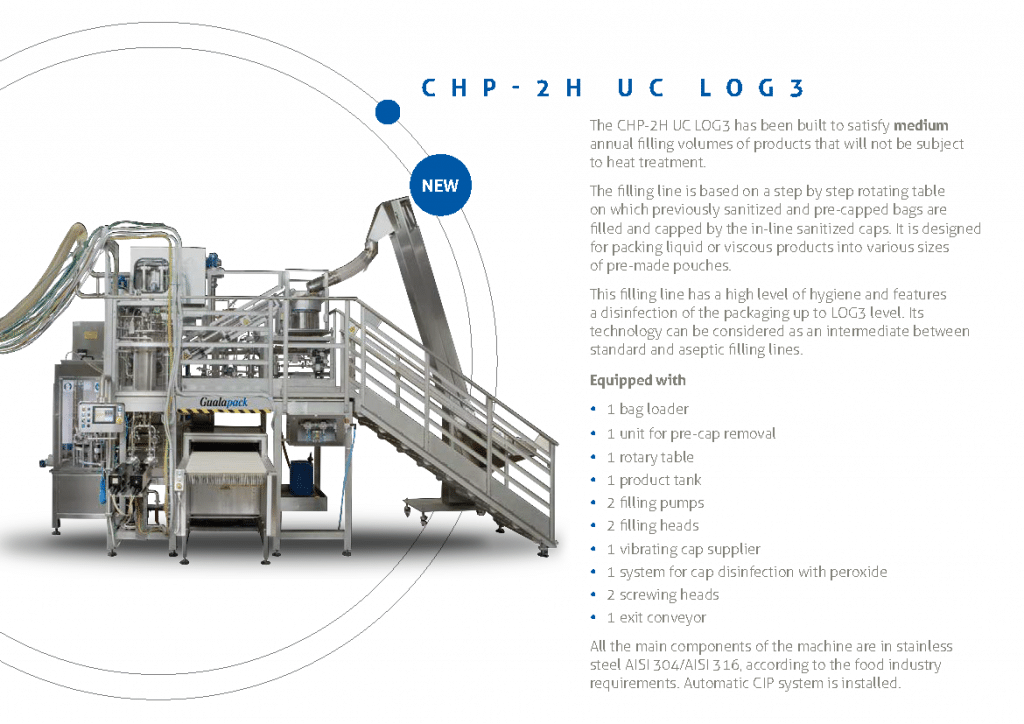

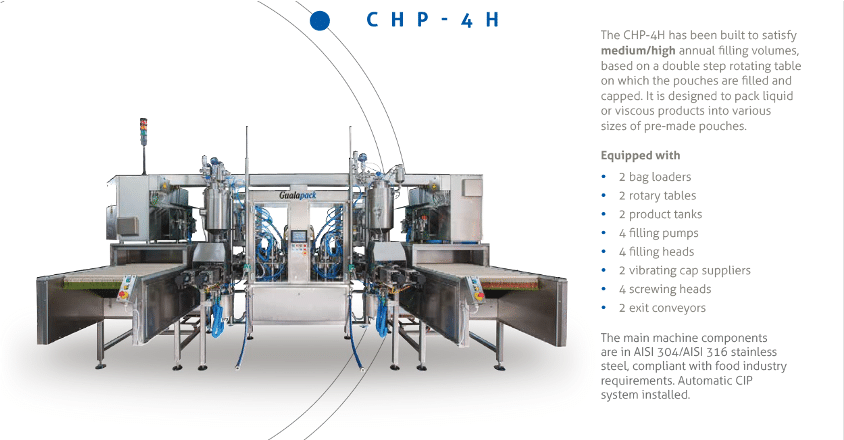

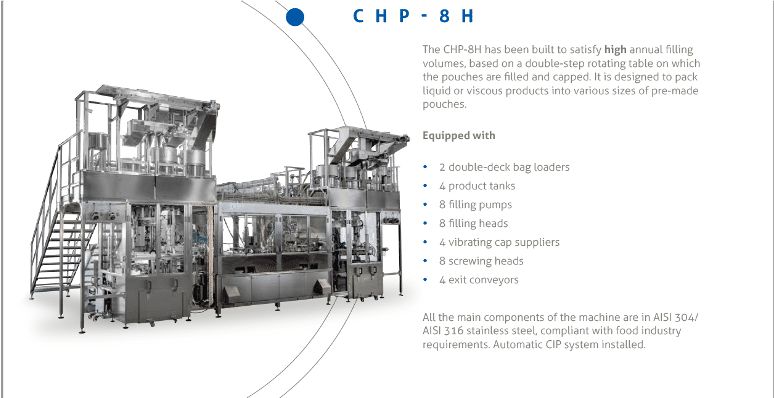

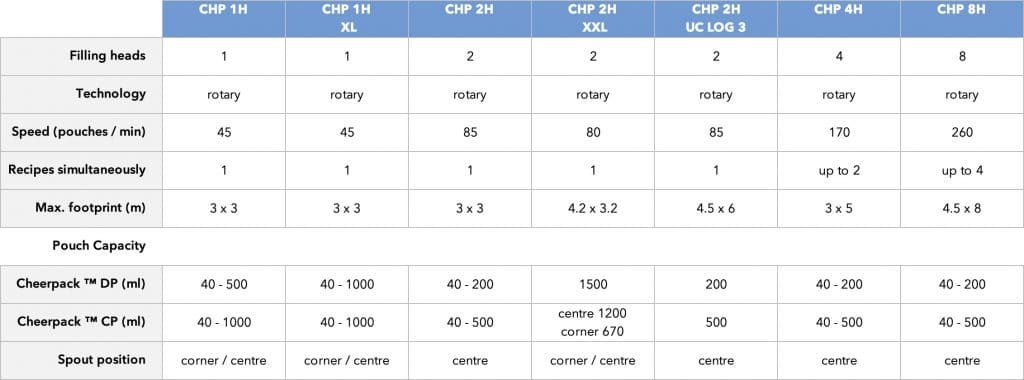

Cheerpack Australia offers filling lines to fill liquid and viscous products into our Cheerpack Spouted Pouches. Designed and engineered in Italy by Gualapack, our machines fill via the spout and support Hot, Cold, Ultra-Clean and Aseptic filling technologies.

The complete range of filling machines and pasteurisation solutions are scalable for different production capabilities, ranging from 45 to 260 pouches per minute.

Our filling equipment aligns seamlessly with our packaging, supporting different pouch shapes and sizes, our spout formats and cap styles.

Main machine components are made of stainless steel AISI 304 / AISI 316. Optional 3A Standards compliance is available on request.

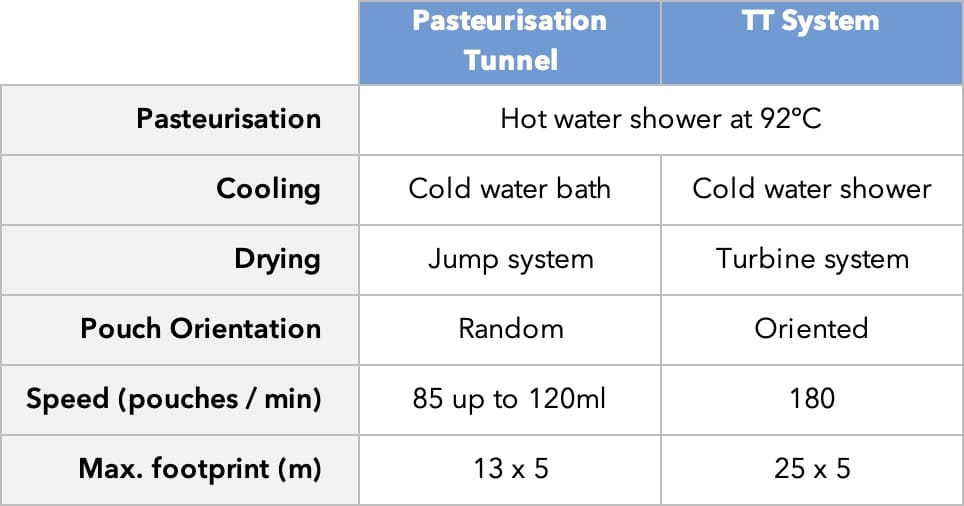

Post Processing Equipment

Equipment dedicated to the pasteurisation of the filled Cheerpack Spouted Pouches via a continuous conveyor from the filling machine.

Upstream and Downstream Equipment

Installing a Cheerpack filler is a simple and efficient process to add capability to your factory. To achieve the full range of benefits from your new solution, we offer world class solutions to complement your Cheerpack filling line. Selecting the right food manufacturing systems, and the right solutions for the end of the line greatly enhances your manufacturing quality and cost and can have a significant impact on increasing factory efficiency and output.

After Sales Support

Equipment installation

Production start assistance

Filling line operator training

Remote and onsite engineering support

Spare parts

Upgrade kits